This article contains my technical opinions and is for general information purposes only. Product references are generic as different brands and products may have different features.

Introduction

It can be useful to address a few key considerations for your underground installations early in your project’s design or installation phase.

Common Underground Cable Products in Canada

Below are the cable products most frequently used in Canada for underground installations:

USEI / USEB: Underground service entry cables with slightly different constructions, meant for use only outside your building. Product preference often varies regionally.\

RWU90: A 1 kV-rated cable suitable for direct burial or installation in conduit.

RW90: A 600 V-rated cable that cannot be directly buried and must be installed in conduit.

TECK90 / HVTECK: A versatile option that can be direct buried, installed in conduit, or encased in concrete. From 300V to 35KV.

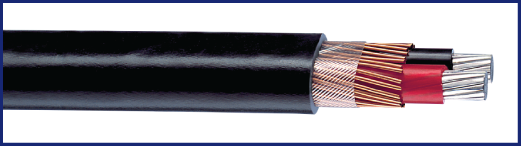

Concentric Neutral Cable: A 5KV to 35KV rated product for underground installations outside your building.

Common Considerations for Underground Runs

Here are some factors and applicable Canadian Electrical Code (CE Code) rules that specifiers and contractors often encounter. CE Code rule 12-012 is always a great place to start looking for what rules might apply. Additional CE Code requirements may apply depending on your specific application.

1. Burial Depth

Refer to CE Code Table 53 for minimum cover requirements for buried cables.

2. Cable Marking

Refer to Appendix B Rule 12-012 for direct burial cable markings – DIRECT BURIAL, DIR BUR, DIRECT BURIAL ONLY, and DIR BUR ONLY. These cable markings indicate they designed for direct burial.

3. Ampacity Tables

Tables D8-D11 provide ampacity values for unshielded applications below 5 kV, while D17 covers 5KV shielded and high-voltage applications.

The ampacities in these tables assume 90°C-rated cables. For 75°C-rated cables, multiply the listed values by 0.886. (See Rule 4-006 for equipment termination temperature requirements.)

If your application conditions (e.g., cable spacing, burial depth, number of parallel runs) differ from those assumed in the tables, you’ll need to perform an IEEE 835 calculation.

4. Surface Transition

As underground runs transition to the surface, installation conditions change, requiring an ampacity calculation for each segment.

Per Rule 4-004 (16), you must use the lower ampacity value of any segment for the circuit ampacity rating.

If the lower ampacity section is shorter than 3 meters and constitutes less than 10% of the total run length, Rule 4-004 (17) allows the use of the higher ampacity value. (Ark Tsisserev provides a great summary of this in the Nov/Dec 2024 issue of Electrical Line Magazine’s Consultant’s Corner.)

5. Deeper Isn’t Always Better

Contrary to common belief, burying cables deeper does not increase ampacity. In fact, the earth acts as an insulator, and IEEE 835 calculations show that deeper burial reduces ampacity.

6. Space Requirements for High-Ampacity Runs

High-ampacity runs often require more space than anticipated. Verify trench width requirements early in the project using CE Code tables or IEEE 835 calculations before you start to dig.

7. Avoid Cable Crossovers

Adjacent cable crossovers can cause mutual heating, leading to ampacity derating.

8. Mechanical Protection

CE Code Rule 12-012 specifies minimum mechanical protection requirements, such as treated planks and concrete coverings.

9. Trench Backfill

Backfill materials should not contain large rocks, debris, or angular materials, as these can damage cables over time and lead to failures.

10. Voltage Drop Considerations

For runs longer than about 100 feet, perform a voltage drop calculation early in the project to ensure your cables are adequately sized.

Final Reminder

Considering these factors during the early stages of your project can save significant costs later. Once trenches or ducts are in place, making changes can become prohibitively expensive. If you need information about product availability or assistance with IEEE 835 ampacity calculations, feel free to contact Texcan.

About the Author

Blair Sackney has 23 years of wire & cable experience gained through major industrial, infrastructure, and commercial projects across North America. As an active IEEE member, Blair is passionate about sharing his expertise on better and safer cable installations.