This article contains our technical opinions and is for general information purposes only. In this article, the term “cable” can refer to a conductor, wire, or cable.

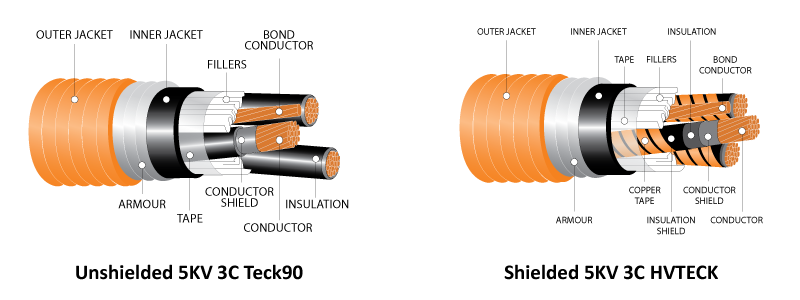

For electrical installations in Canada with voltages up to 5KV, CSA Standards currently allow us to use either shielded or unshielded 5KV cables. Due to several recent customer inquiries on this topic, we have written this article to examine some of the merits of both options to help industry professionals select the best product for their application.

Unshielded 5KV Teck90 cables are the most commonly specified products for Industrial and Commercial 5KV power distribution applications, but shielded 5KV cable usage is quickly growing. Unshielded 5KV is proven to be reliable in long term applications.

Changes in the 2005 US National Electrical Code (NEC) introduced shielding as a requirement for power cables in circuits of 2.4KV and higher in the US with a few minor exceptions. Meanwhile, Canada has continued to allow the use of unshielded 5KV cables. A few years ago, Texcan began inventorying large quantities of both unshielded 5KV Teck90 and copper tape shielded 5KV HVTECK cables to allow electrical designers the ability to confidently specify either product. Prior to that, long lead times and large minimum order quantities effectively discouraged many projects from using shielded 5KV HVTECK cables.

A 2005 EC&M article, “Behind the 2005 NEC Changes: 310.6 Shielded Cables”, described NEC code panel members having a mix of opinions on the safety concerns around using unshielded 5KV cables. Some members believed unshielded cables are perfectly safe and perform well when properly installed by qualified personnel. Other panel members had safety concerns regarding possible standing voltages in long runs that could pose a touch hazard. As always there are pros and cons of every product type that should be considered based upon application specifics.

Pros for using shielded 5KV HVTECK cables:

- Can test cable integrity by testing between the phase conductor and the integral conductor shield instead of only to a separate bonding conductor.

- Cable shield ground plane fully encircles the conductor reducing insulation electrical stress, arguably increasing cable lifespan in some applications.

- Grounded shields can be used to carry a portion of the fault current to ground.

- Grounded shields reduce the risk of touch hazard shocks by draining surface charges to ground.

- Stress cone terminations prevent electrical tracking and ozone related failures.

- Shields might be required by certain types of ground fault detection systems to monitor and indicate any stray leakage currents.

Cons for using shielded 5KV HVTECK cables:

- Requires more expensive/larger “stress cone” style terminations.

- Additional material and installation costs.

- Terminations may be difficult to fit in equipment.

- Only available only in 2AWG and larger compared to Unshielded 5KV Teck90 being available down to 6 AWG

One factor often considered in switching to shielded 5KV HVTECK cables is longer cable life. This is a tough one to prove as there has been no testing of this. However, it is intuitive to many engineers that electrical stresses will be lower on the cable insulation with the shield acting as a ground plane around the conductor. Stress cone style terminations will also prevent possible partial discharge arcing at the terminations resulting in more reliable cables. On the other hand, Unshielded Teck90 cables have proven their long-term performance in harsh Canadian applications when installed correctly.

Both products have shown to perform extremely well in harsh conditions. There have been unshielded cable failures that led some end users to consider changing their specs to shielded. Root cause analysis of the failures I have seen were inconclusive on whether a shield would have extended the life of the cables and no industry testing has been done on this topic to prove its validity. Cable failure modes are a complex mix of factors that commonly don’t point to an obvious smoking gun. Many of the failures I have seen suggest possible installation issues or improper testing procedures.

There is a case to be made for each product and the pros and cons have been greatly debated amongst industry experts. Product selection will often be based upon the specifics of the application such as installation method and operational life requirements. We are always available to assist in your product evaluation for your unique applications.

For more information on Teck Cables, read our follow-up article on TECK Cables - Why They Are Such A Great Design.